Category: Union News

-

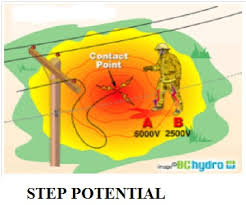

Step Potential – Information Video

Keep your distance and learn how “step potential” can injure or kill you just by walking near downed wires. Click on the video to watch about step potential.

-

WorksafeBC – Roles, rights & responsibilities of Workers

On a worksite, everyone has varying levels of responsibility for workplace health and safety. You should know and understand your responsibilities — and those of others. If you’re a worker, you also have three key rights. Your rights Right to a healthy and safe workplace Right to safety training and orientation Right to refuse unsafe work…

-

IBEW NextGen … the next generation of Electricians

The next generation of IBEW members needs to be ready to take the helm. Click on the video to watch …

-

The Birthplace of a Union to Be Reborn as a Museum

The man who sparked a movement is getting a museum to honor his memory. At a time of terrifyingly high mortality rates and paltry pay in the new field of electrical work, Henry Miller knew what needed to be done, and he dedicated his life to making it happen. From the St. Louis boarding house…

-

IBEW local union #1003 Annual Picnic was fun and there was lots of food.

Thank you to everyone that showed up for the IBEW 1003 Annual Picnic !! Thank you especially to those that helped out, Logan Lynn and Tim Lucas the chefs extraodinaire, Ray Keen, Dale Anderson, Mike Kinaken. Also thanks to Ruth Anderson for some direction when we were wandering around bumping into walls. Thanks also to…

-

Does it Pay to Work Union? Yes. And Here’s Proof.

A new study says union construction members in Minnesota get $5.59 back in income for every $1 they pay in union dues. The findings come in a new analysis from the Midwest Economic Policy Institute, which found that union construction members paid a yearly average of $1,381 in union dues and fees, but that they…

-

IBEW What About the Non-Union

Canadian electricians talk about their experiences before coming to the IBEW. Click on the video to watch …

-

IBEW: The Henry Miller Story

Henry Miller, who died more than 110-years ago, was the founder, first president and driving force behind the first union of electrical workers in North America the International Brotherhood of Electrical Workers. Click on the video to watch … (sorry it’s a bit quiet)

-

Safety – Always wear your Safety Glasses on the job

Safety eyewear for workers who wear glasses or contact lenses If your work exposes your eyes to hazards such as dust or chemicals, or to the risk of impact with tools, materials, or flying debris, you must wear safety eyewear. This requirement also applies to workers who wear prescription glasses or contact lenses. Regular prescription glasses…

-

Lineman Gloves and How They Are Made – IBEW HourPower

Click on the video to start it playing …